WATER RESERVOIR DREDGING

Water is one of our most valuable natural resources, essential for drinking water, irrigation, recreation, and hydropower. Reservoirs play a key role in capturing, storing, and protecting this resource. However, due to erosion, heavy rainfall, or deforestation, sediment such as sand, silt, and organic matter accumulates over time. This build-up reduces storage capacity and negatively impacts water quality. Reservoir dredging restores this lost capacity, prevents clogging of dams and intakes, and safeguards the long-term stability of water supply systems. It is not simply an operational task, it is a strategic necessity for sustainable water management.

WATER RESERVOIR DREDGING TOOLS

Each dredging project requires a tailored solution depending on the type of soil and sediment present.

- Cutter Suction Dredger (CSD): Best suited for compacted or harder soils, such as clay or consolidated tailings. Equipped with a rotating cutter head, it effectively loosens solid layers for removal.

- Plain Suction Dredger: Ideal for fine, free-flowing sediment such as sand or soft silt. This type relies on hydraulic suction power, making it highly efficient in lighter conditions.

Both options are available in electrically powered versions, ensuring lower emissions and reduced environmental impact.

Water reservoir Cierny Vah. Sunset in Slovakia, Liptov

Solutions for water resevoir dredging

Plain Suction Dredgers

Electric plain suction dredgers are often deployed in sensitive environments, such as drinking water reservoirs. Since they operate on electricity, their ecological footprint is significantly smaller, with reduced noise and minimal disruption to aquatic ecosystems. This makes them an excellent choice for projects where environmental preservation is a top priority.

Cutter Suction Dredgers

These versatile dredgers are used when projects involve a mix of fine silt and tougher materials. Cutter suction dredgers can be applied in both maintenance operations and larger-scale dredging projects, making them suitable for reservoirs with variable sediment types.

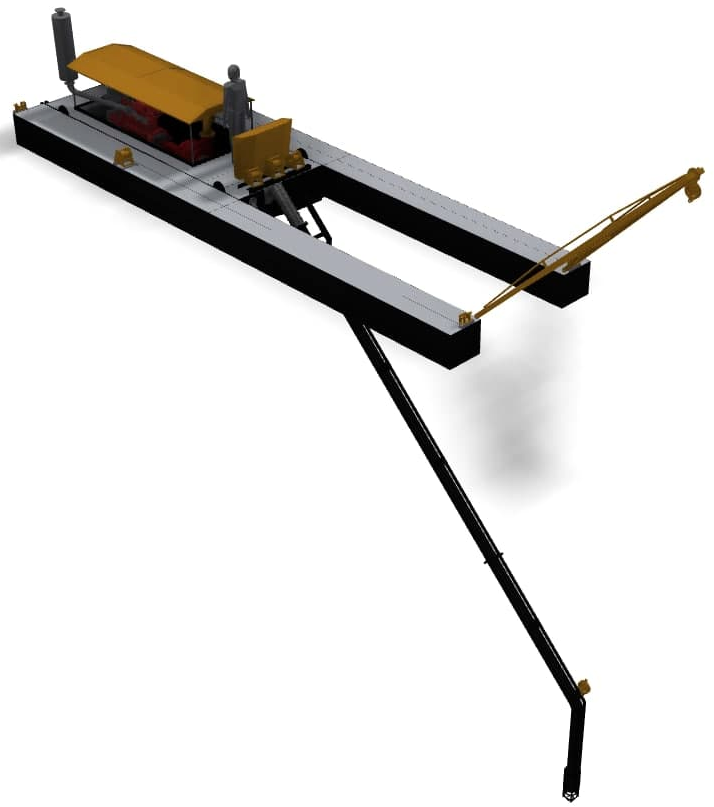

Plain Suction Dredgers

Dredging water reservoirs can be sensitive environments to dredge in. ECTMarine delivers plain suction dredgers in electric powered versions.

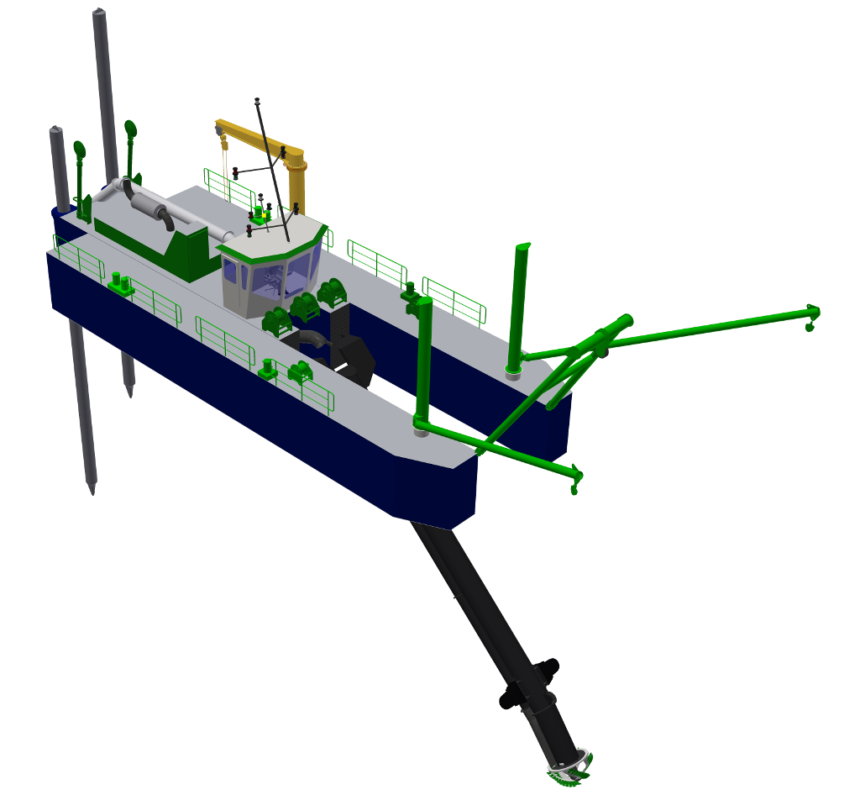

Cutter Suction Dredger

Cutter Dredgers can be functional in a wide variety of application which include dredging of water reservoir dredging

How to make the right choice in dredging equipment

Selecting the right dredging equipment is more than just a technical decision. It is a strategic investment that affects project timelines, environmental compliance, and long-term operating costs. Whether you are managing a small reservoir, maintaining a navigational channel, or executing a large-scale land reclamation project, the type of dredger you choose will directly determine efficiency, cost-effectiveness, and sustainability. With many options available, including cutter suction dredgers, plain suction dredgers, water injection dredgers, and compact modular systems like the Quick Dredge, it can be challenging to decide which is best suited to your project. Each type of dredger has specific strengths depending on soil conditions, environmental regulations, and project size. In this guide, we break down the key factors that matter most when making the right choice, so you can maximize efficiency, minimize environmental impact, and ensure long-term value from your investment.

1. Soil composition

A geotechnical survey is always the starting point. Soft silt and mud are best managed with plain suction dredgers or water injection dredgers. Fine to medium sand is more effectively handled with cutter suction dredgers, which provide greater control. Compacted soils or clay require cutter suction dredgers with powerful engines and durable cutting heads. Understanding soil type prevents the risk of choosing underpowered machines or experiencing unnecessary wear.

2. Environmental Regulations

Dredging projects are increasingly subject to strict emission and turbidity standards. Water injection dredgers cause minimal disturbance, use less fuel, and are often easier to approve in regulated zones. Selecting the right option at the planning stage helps prevent costly delays in the permitting process.

3. Project Size and Location

Different projects require different levels of mobility and power. Small reservoirs or remote sites are well served by the containerized Quick Dredge, which is easy to transport, assemble, and operate with limited resources. Medium to large infrastructure projects such as ports, navigational channels, and mining ponds benefit from full-scale cutter suction dredgers or plain suction dredgers. Matching the dredger to the scale of the project reduces both transport costs and operational inefficiencies.

4. Operational Efficiency

Each dredging method has unique advantages. Plain suction dredgers are best suited for fine sediments and high-volume removal. Cutter suction dredgers are designed for tougher deposits, clay, or compact sand where more precision is required. Water injection dredgers use natural water currents to relocate sediment and can lower costs by up to 50 percent in suitable conditions. Choosing the right method improves fuel efficiency, dredge cycle time, and overall project output.

5. Maintenance and Longevity

Equipment evaluation should go beyond upfront purchase price. Availability of spare parts and a reliable service network are critical for reducing downtime. Custom-built dredgers should be considered only when long-term service agreements are guaranteed. Modular construction and ease of transport make repairs and upgrades more efficient, extending the life of the equipment.

6. Cost Versus Sustainability

Modern projects require a balance between financial efficiency and environmental responsibility. Lifecycle costs should be compared rather than focusing only on the initial investment. Energy use, whether fuel-powered or electric, must be considered based on local infrastructure. Compliance with emission standards and sediment relocation regulations is essential for sustainable operations. Balancing these aspects ensures environmentally responsible dredging without compromising profitability.

Learn more about our previous dredger projects

At ECTMarine, we are proud to showcase a strong track record of successful cutter suction dredger projects around the world. Each project highlights our dedication to quality, innovation, and client satisfaction. From tackling complex engineering challenges to delivering custom-built dredging solutions, our work demonstrates both expertise and reliability.

Explore our portfolio to see how ECTMarine has helped clients achieve efficient, sustainable results and why we are a trusted partner in the global dredging industry.

This project was sold in 2020 and was successfully completed in 2022. The dredger is a Cutter Suction type with a total installed power of 1286 kW and a mixture production of 4000 m3/ hour. This dredger is designed and built to the latest standards and developments and has safety features such as a pump bulkhead to prevent flooding in case of a pump failure. The dredger got the name “BACALAR” when it entered the dredging fleet of SEMAR in 2022. The max dredging depth is 14 meters with 180kW cutter power. To increase dredging effectiveness the BACALAR is fitted with a spud carrier.

This project was sold in 2016 and was successfully completed in 2017. The dredger is a Cutter Suction type with a total installed power of 632 kW and a mixture production of 2500 m3/ hour. The dredger has been working in river Brahmaputra where it has been making sure the water inlet is kept free of sand brought by the river from the mountains. The water inlet provides water to the city of Guwahati.

News

News